- October 20, 2023

- by Kaizen

- Brass Nut, Fasteners and Fixing

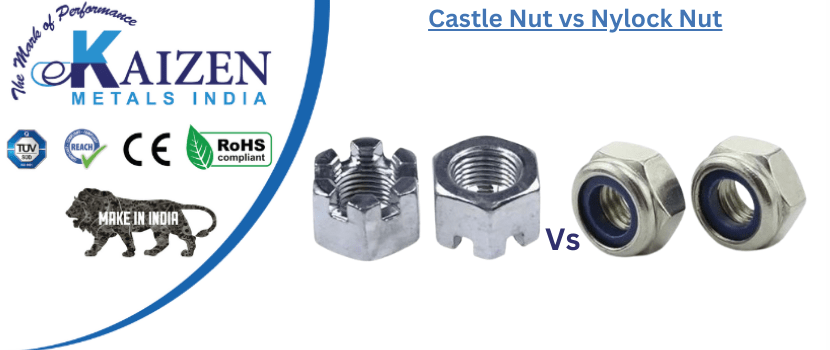

Castle Nut vs Nylock Nut – What’s the Difference

What is Castle Nut?

A fastener used to hold together parts and assemblies is called a castle nut, slotted nut, or castle wheel nut. It has two slots cut into its sides so that when it is tightened with a cotter pin or wire, the component it secures cannot be released. They are frequently utilized in bicycle frames, industrial building, and automotive applications. Its form, which resembles an old fortress tower (or “castle”), gave rise to the name

What is Nylock Nuts?

To lessen the chance of loosening as a result of vibration, Nylock nuts are utilized in fastening applications. They are made up of an inner nylon insert that causes friction between the threads and keeps them from unscrewing and an exterior hexagonal metal shell. Nylock nuts are available in a variety of sizes and materials, including brass, aluminum, steel, and stainless steel, making them appropriate for practically any application.

Difference Between Castle Nut and Nylock Nuts

1) Structure

Castle nuts are hexagonal in shape and include holes at the top where a cotter pin may be inserted to prevent the nut from coming loose. Nylock nuts, on the other hand, are hexagonal and have a nylon insert at the top of the nut. A locking mechanism is provided by the nylon insert, preventing the nut from backing out or coming free as a result of vibration.

2) Functionality

When it’s important to hold a bolt that is frequently adjusted or removed, such as in the case of wheels, steering components, and suspension components, castle nuts are frequently utilized. Access to the nut is made possible by simply removing and replacing the cotter pins. On the other hand, Nylock nuts are utilized when there is a high likelihood that the joint will undergo a lot of vibration stresses, increasing the risk of the nut breaking free. They are perfect for situations where safety-related loosening is a concern.

3) Tightening Method

Castle nuts are fastened with a cotter pin after being tightened with a socket wrench and put into the previously specified slots. On the other hand, Nylock nuts include a nylon insert locking mechanism that allows for hand tightening. They are the best option in instances when it is challenging to reach and spin the bolt’s nut.

4) Material

While the nylon component in nylock nuts is made of nylon, castle nuts are normally constructed of steel or iron. Nylock nuts are more costly than castle nuts due to this characteristic. Steel or iron nuts have a high tensile strength, which makes them perfect for use with heavy equipment and situations where a lot of power is needed to keep the joint in place.

4) Material

Castle nuts and nylock nuts are both solid fastening options in terms of dependability. The castle nut system’s cotter pin adds an additional level of protection against the nut coming undone. Similar to nylock nuts, the nylon insert keeps them firmly in place, lowering the possibility of loosening and separation.

Conclusion:

In conclusion, the construction, functioning, tightening techniques, material, and dependability of castle nuts and nylock nuts vary. Nylock nuts work well for joints that are prone to vibration or loosening, whereas castle nuts are best for routine adjustments. Due to its structural design, castle nuts are better suited for situations where a lot of force is needed to hold the joint in place. Nylock nuts are more pricey but provide a more secure locking mechanism for fasteners. Which nut to choose ultimately comes down to the particular application and desired level of security.