Grounding and Bonding

Providing an electrically conductive path between a dispensing container, a receiving container, and an earth ground is known as Grounding and Bonding.

This prevents the buildup of static electricity and sparks that could start a flash fire if fuel and air are mixed in a flammable way.

Therefore, the differences between bonding and earthing can be summarized as follows: Earthing is the stuff ‘in’ the ground, and; Holding is the stuff ‘over the’ ground.

Consequently, knowing that some “stuff” from the earthing system will be above ground level.

The purpose of the grounding (earthing) procedure is to ensure that the aircraft and the ground remain electrically connected.

Bonding with electricity: The holding activity is for the electrical congruity between the airplane and a ground gear, or between a hardware and the airplane structure.

Earthing is essentially used to stay away from electric shocks.

When the electric system overloads, grounding is primarily used to unbalance the system.

Earthing is situated between the gear body and the underground pit under the earth pit.

Connecting electrical equipment to a common reference ground or earth is known as grounding.

Safeguarding is utilized for resistance (safeguarding against outside obstruction) and discharge (forestalling impedance to be emanated).

The personnel’s safety within a building comes first. The electrical system’s proper bonding and grounding could be the reason an employee in the building doesn’t get shocked accidentally and can go home that night. That much is at stake.

Sensitive equipment and low-voltage signals are two additional items that could be harmed by improper bonding and grounding. Despite the fact that these items may be related to safety, their usability is also essential to production.

Grounding and Bonding are essential electrical safety practices that ensure electricity flows safely, reduce shock hazards, and protect equipment from damage. Grounding directs fault current to the earth, while bonding connects conductive parts to ensure equal electrical potential — preventing dangerous voltage differences.

Key Features to Highlight Grounding and Bonding

NEC/IEC compliant grounding components

Improves safety and reduces shock hazards

Protects appliances and electrical systems

Prevents lightning and fault current damage

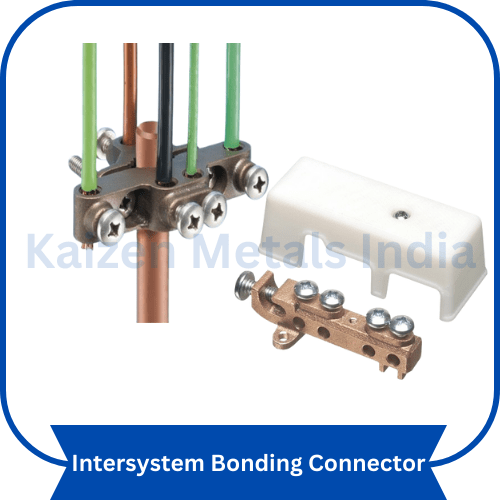

Ensures equal potential between metal parts (bonding)

Suitable for residential, commercial, and industrial systems

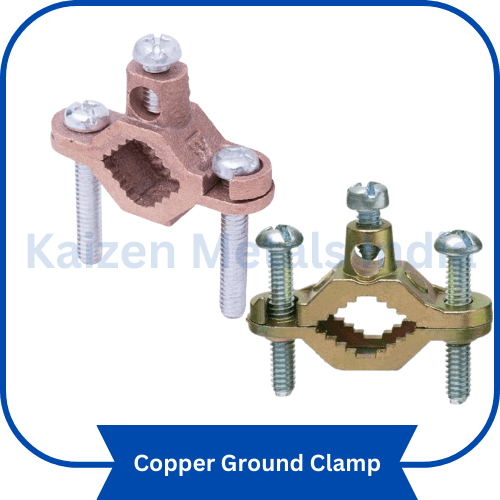

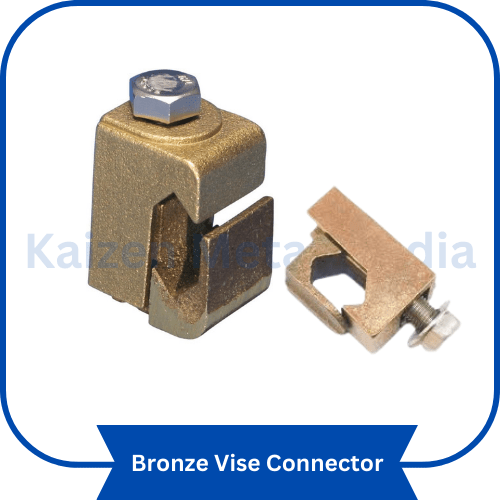

Available in copper, brass, steel & alloy materials

Categorize of Grounding and Bonding

Grounding and bonding

Electrical grounding

Electrical bonding

Equipment grounding

Grounding systems

Bonding conductors

Grounding wire

Safety grounding

Earthing and bonding

NEC grounding and bonding

Electrical grounding components

Grounding and bonding for buildings

Industrial grounding systems

Grounding & bonding for electrical panels

Ground rod installation

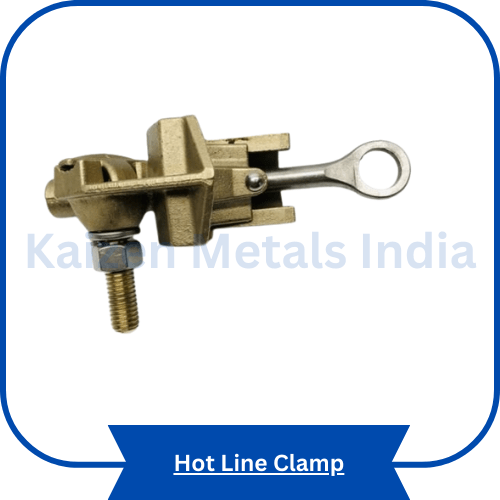

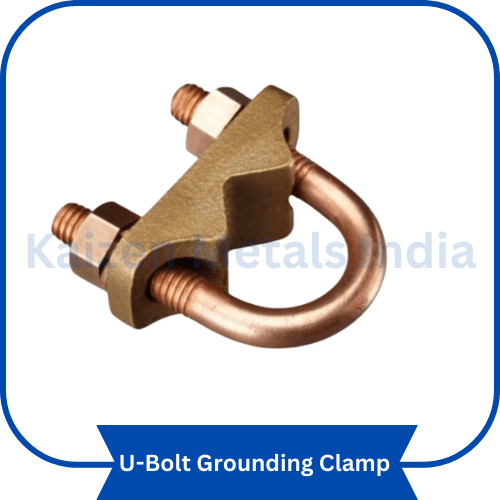

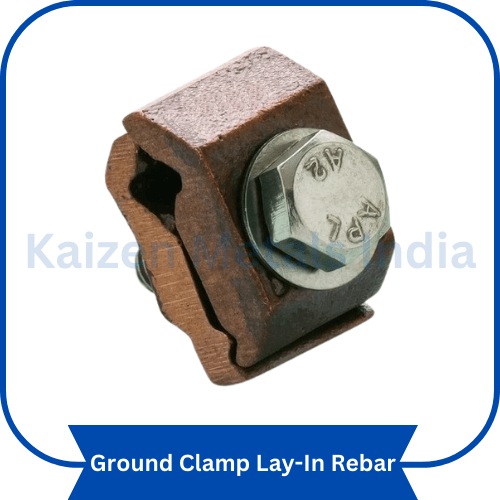

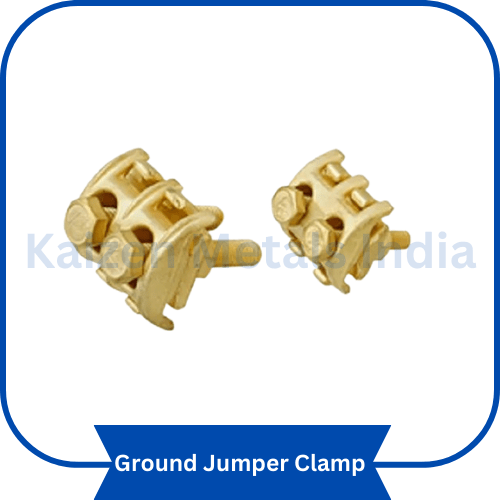

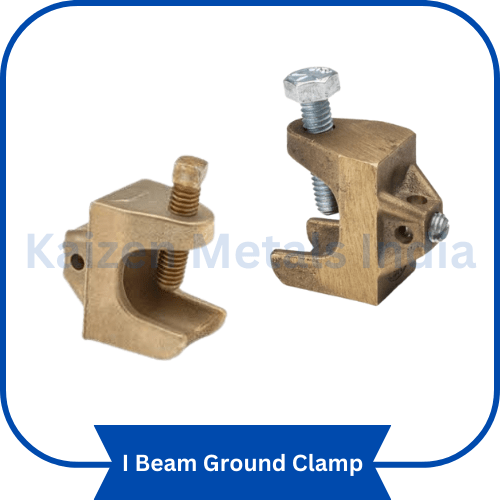

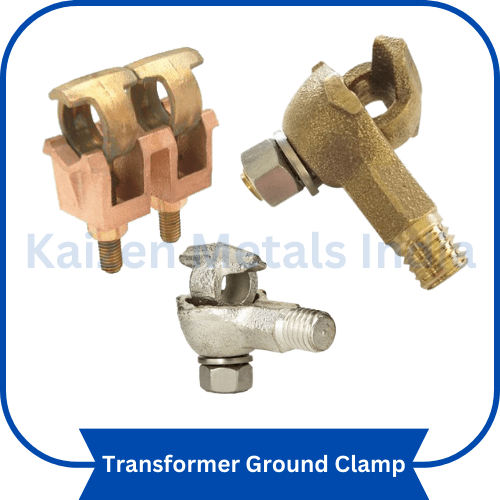

Grounding connectors and clamps

Bonding jumpers

Grounding busbar

Lightning protection grounding

Ground fault protection

Electrical safety grounding solutions

Buy grounding and bonding equipment

Grounding clamps suppliers

Grounding rod manufacturer

Grounding kits for electrical systems

Earthing & bonding components wholesale

NEC-compliant grounding products

Sample Time: Available in 5-10 days for different items.

Drawing Format: CAD / PDF / DWG / IGS / STEP.

Packaging: Standard package, Carton box or Pallet, As per customized specifications

Shipping: DHL, FEDEX, UPS and By Sea or as per client’s requirements.