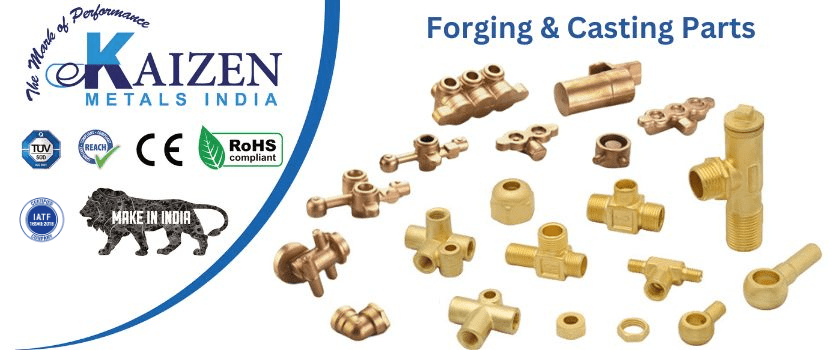

Forging & Casting Parts

We have practical experience in the creation of Producing and Projecting Parts and metal fashioning parts, Forging & Casting Parts.

For different businesses, like water valve and line fittings, plumbing and clean fittings, agrarian gear, auto parts, LPG and CNG valve fittings, electrical and designing gathering,

we can make any kind of metal producing parts, parts, and fittings.We can likewise produce and machine metal parts.

As indicated by the plans and determinations of the client, we have an exceptional assembling office for metal producing parts.

We give the Sand-Impacting and Suspending Offices for Surface Completion on the Metal Fashioned and Projecting Parts, which works on the productivity of the completing on the Metal Manufacturing and

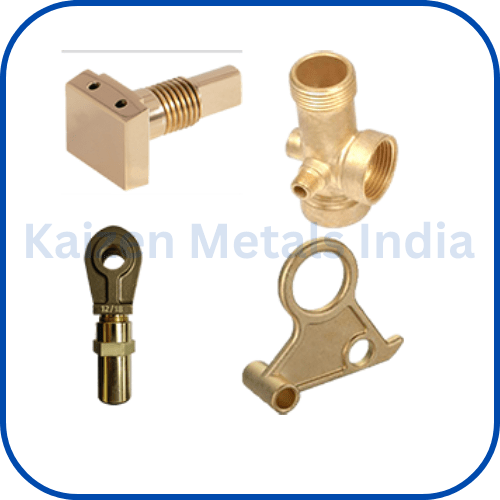

Metal might be formed utilizing two extremely particular assembling strategies called manufacturing and projecting.

Metal is warmed all through the projecting system until it is liquid.Then, at that point, to get the expected shape, it is filled a form or compartment.

Material is pushed or pounded into a specific shape during the manufacturing system while as yet being strong.

For what reason do we choose to fashion, then?

Metal billets are precisely rolled, squeezed, pounded, or generally molded into a particular shape during manufacturing methods while they are as yet strong.

By empowering metallurgical re crystallization to happen, the warming and twisting cycle refines the inner grain design of the metal, bringing about a steady construction all through the metal structure.

Unique

The metal is reinforced during this interaction, which additionally builds its protection from effect and shear harm.

Key Features to Highlight

High tensile strength and durability

Superior dimensional accuracy

Rust-resistant and wear-resistant material options

Supports complex shapes (casting) & high-strength designs (forging)

Available in steel, aluminum, brass, iron & alloy metals

OEM & custom manufacturing options

Suitable for heavy-duty industrial applications

Forging & Casting Parts Description

| Key Features : | » Made from high quality & tested raw materials to give excellent performance.

» High strength for safety & long-run applications. » Custom marking as per require during forging process. » Better solution for large components. » Customized as per client’s needs. |

| Material : | » Forging Brass As Per BS 218

» Any Special Brass Material Composition As Per Customers Requirements |

| Threads : | » ISO Metric MM, PG, BSW, BSP, BSB, BSF, BA, NPT, NPTF, UNC, UNF, UNEF etc

» Almost any threads as per custom specification |

| Finish : | Natural, Nickel Plated and Any Special Coatings as Per Customers Requirements |

Forging parts

Casting parts

Metal forging components

Metal casting components

Precision forging parts

Precision casting parts

Drop forged parts

Investment casting parts

Sand casting parts

Custom forging and casting parts

OEM forging parts manufacturer

OEM casting parts supplier

High-strength forged components

Stainless steel casting parts

Aluminum forging parts

Brass casting components

Industrial forging parts

Automotive forging and casting parts

Heavy machinery casting parts

Closed-die forged parts

Open-die forged components

Buy forging parts

Buy casting parts

Custom forging and casting services

Forging & casting parts manufacturer

Precision metal parts supplier

Bulk forging and casting components

Sample Time: Available in 5-10 days for different items.

Drawing Format: CAD / PDF / DWG / IGS / STEP.

Packaging: Standard package, Carton box or Pallet, As per customized specifications

Shipping: DHL, FEDEX, UPS and By Sea or as per client’s requirements.